Design & Engineering

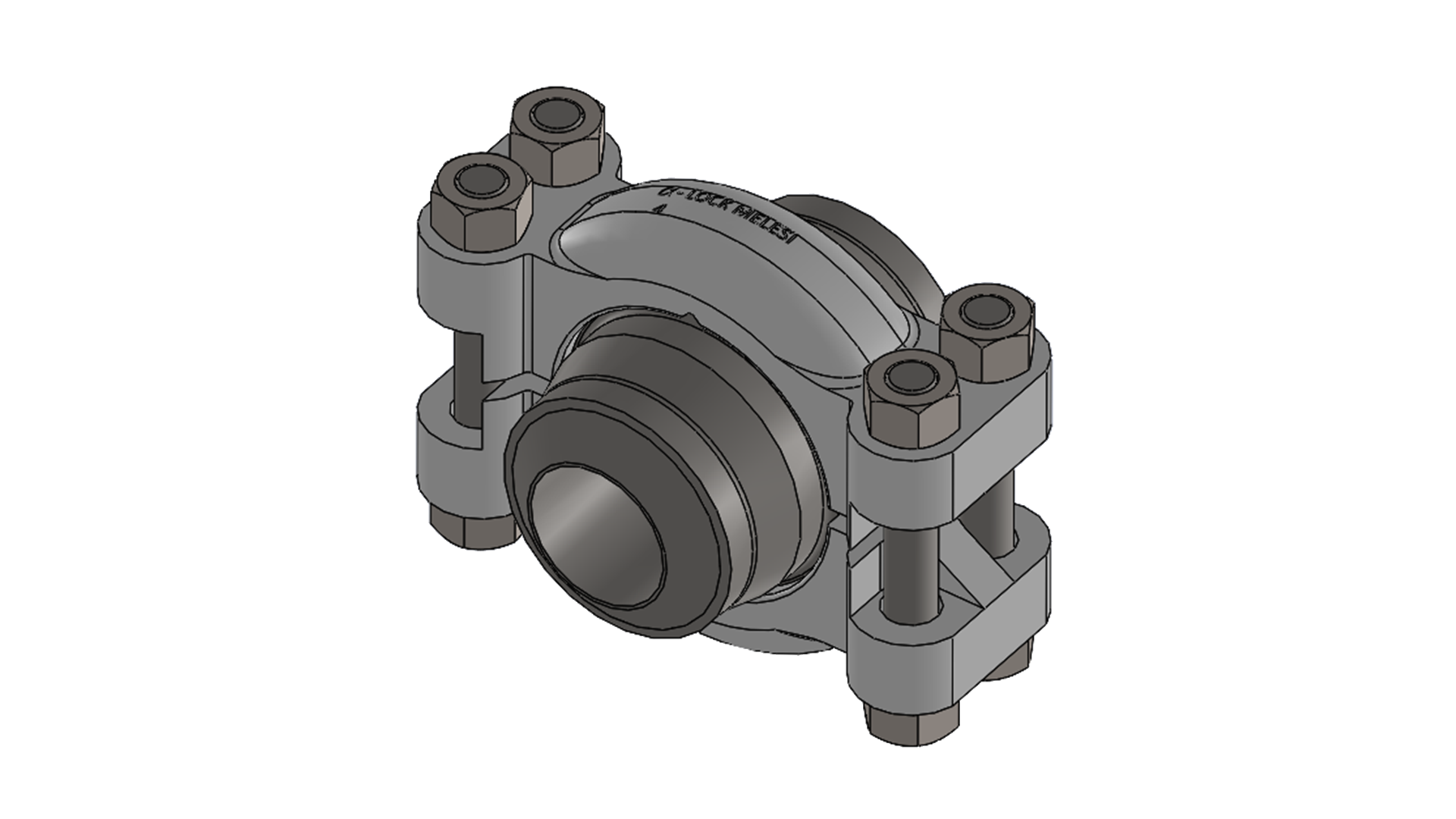

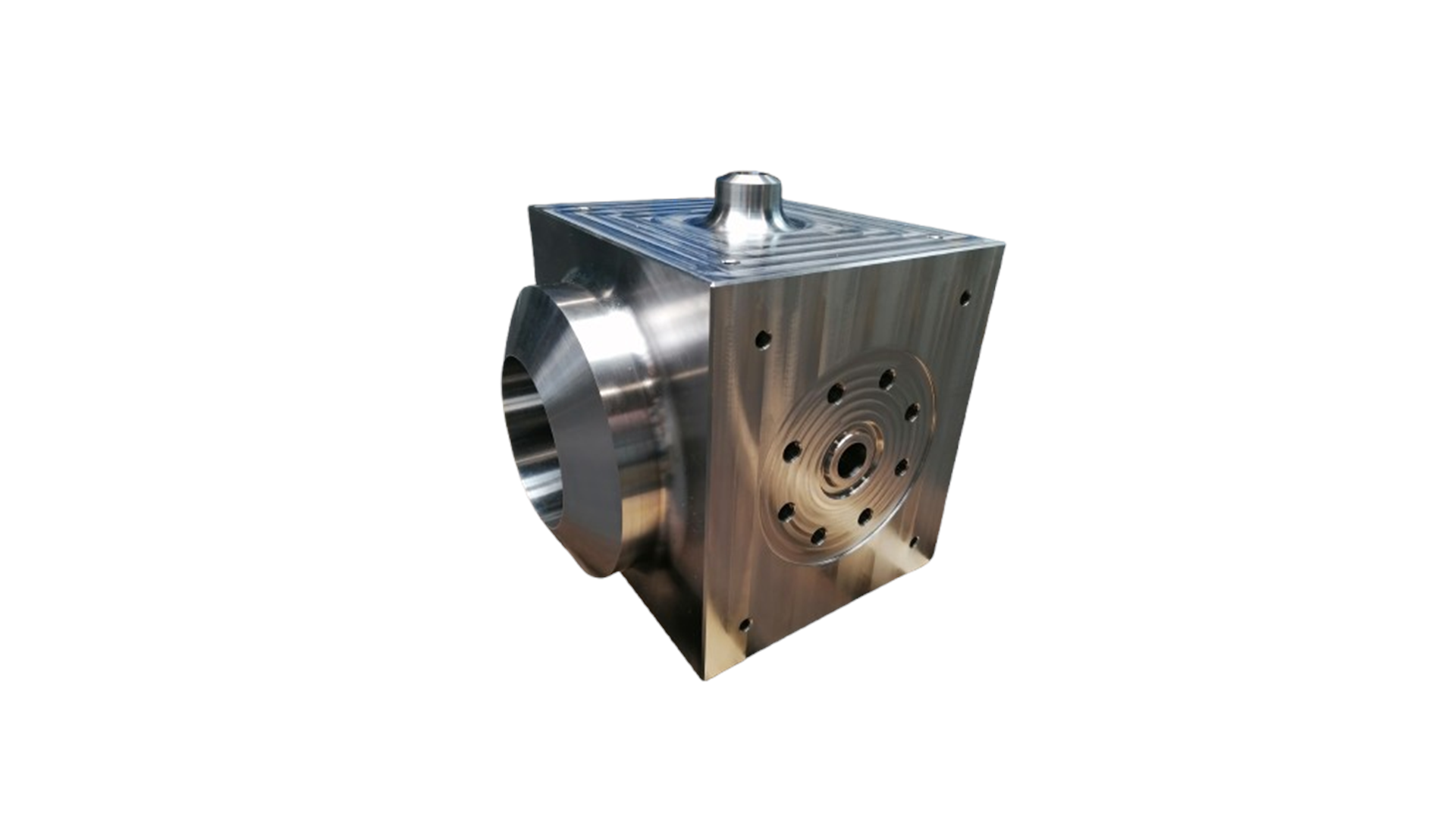

Specification analysis and design are the first steps in the product engineering process, which concludes with final validation.

Process engineering optimizes forging, heat treatment, and machining processes to achieve products of absolute quality.

Tecnology and know-how confirm the validity of the results through system behavior simulation and pratical tests performed on the products.

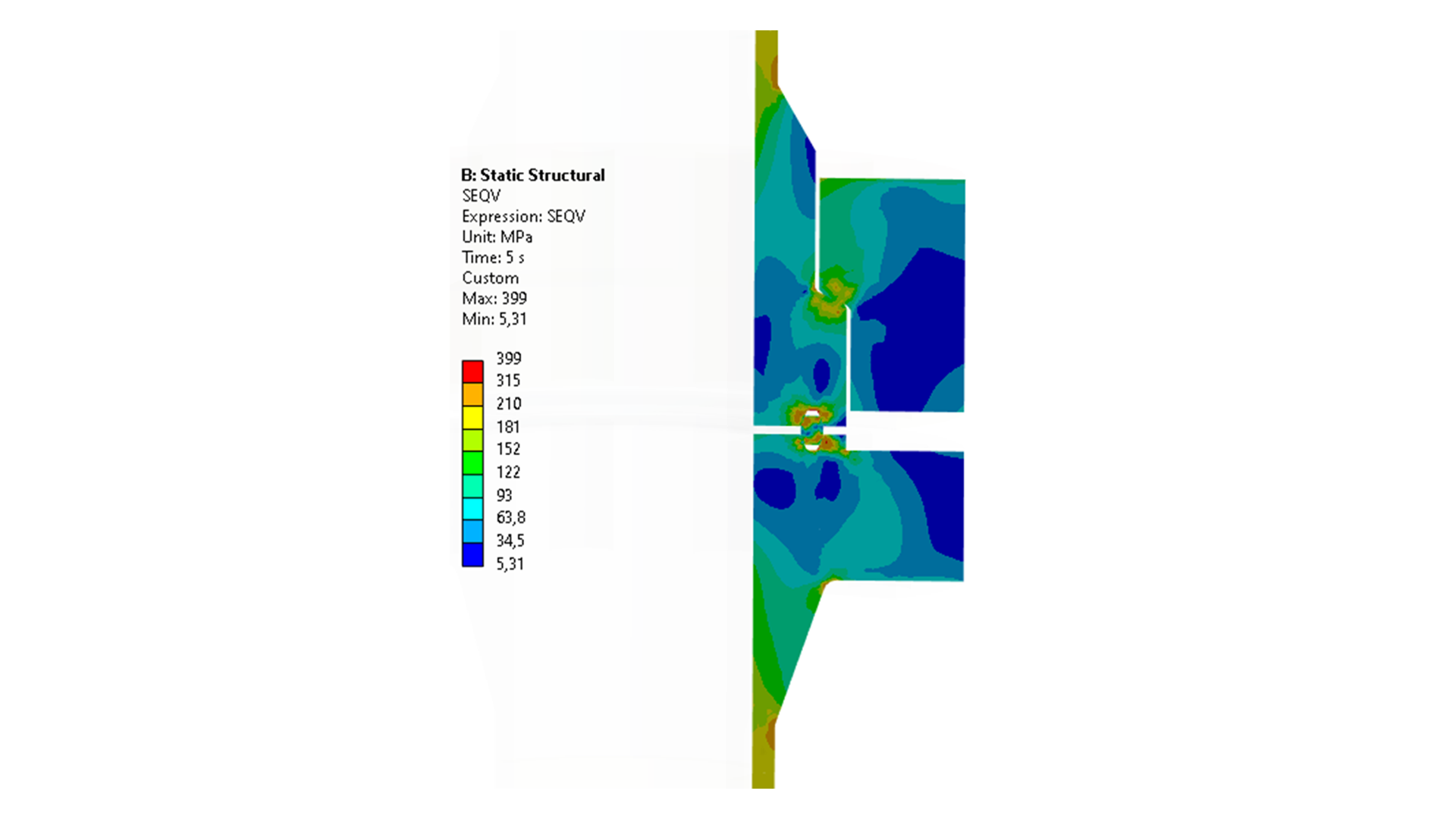

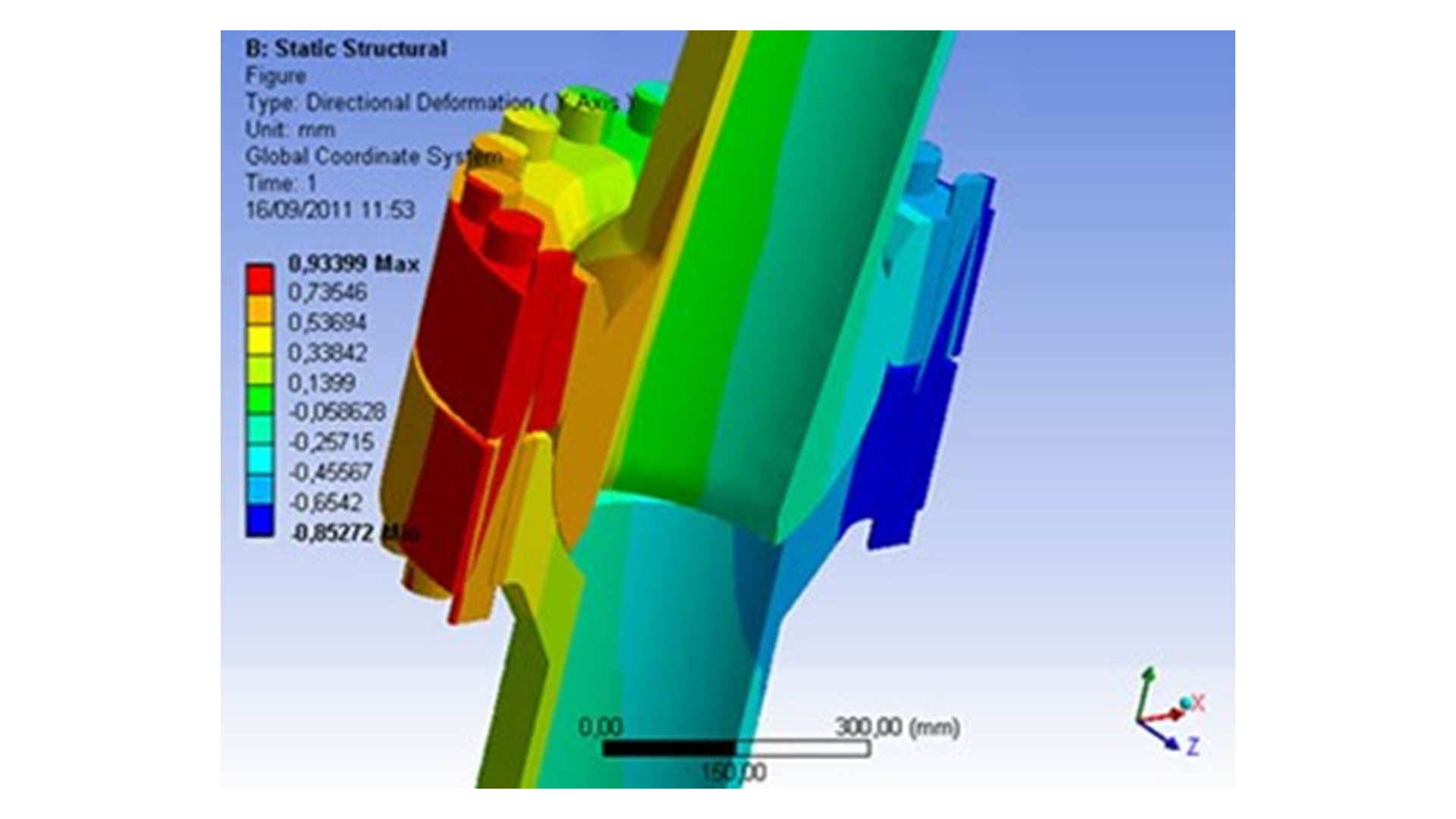

Finite element analysis

The FEA simulation method, in accordance with the main industry standards, allows an approach to the real behavior of the system, enabling design improvements to optimize product performance.

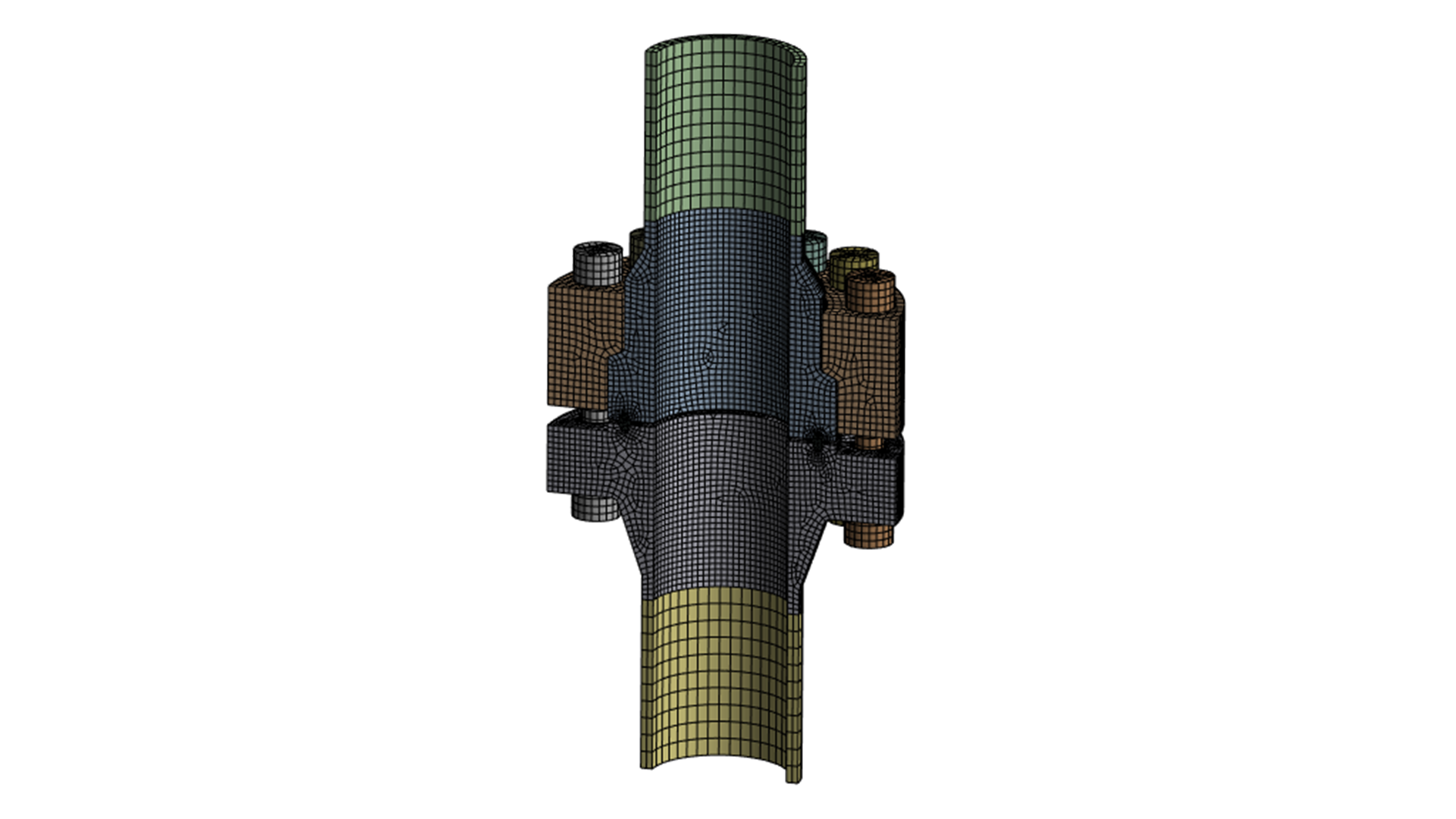

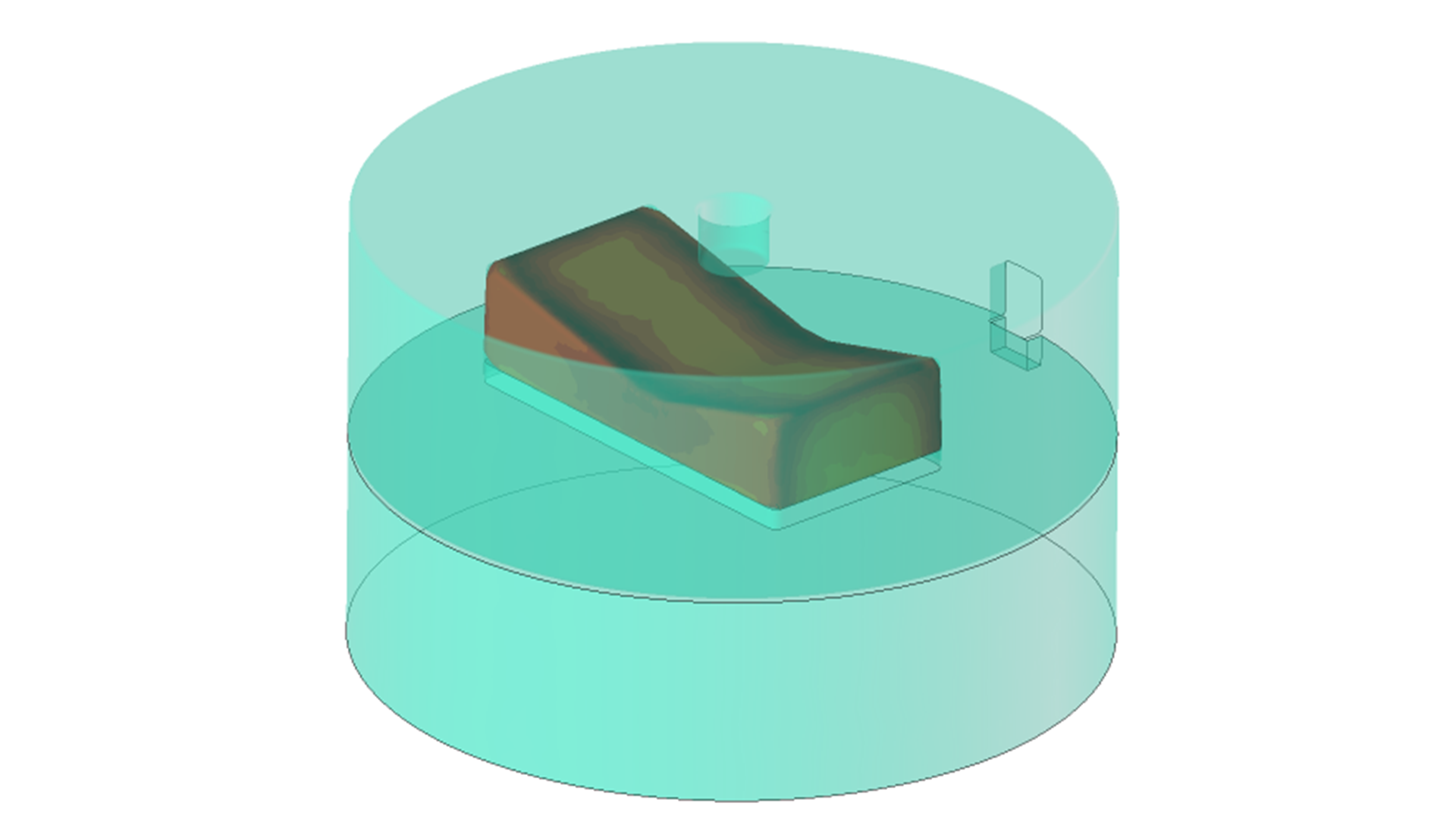

Forging process simulation

Study of the forging and rolling phases to optimize process steps, material flow, and equipment to achieve the best performance of the final component.

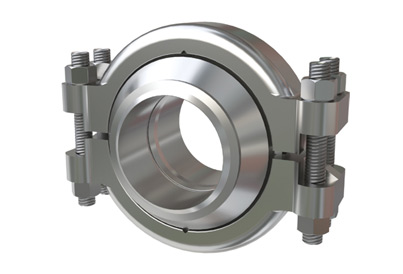

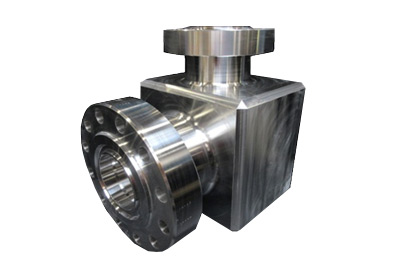

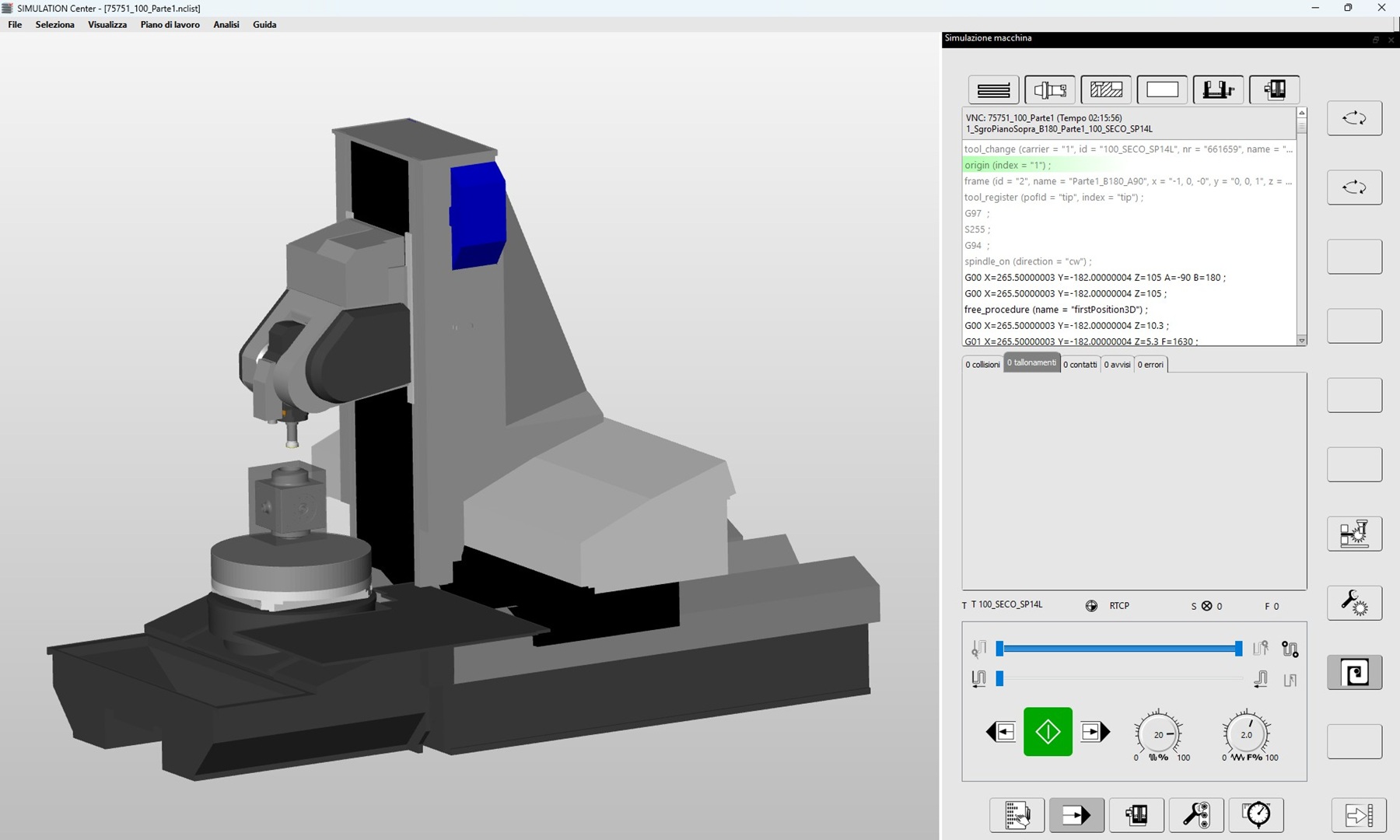

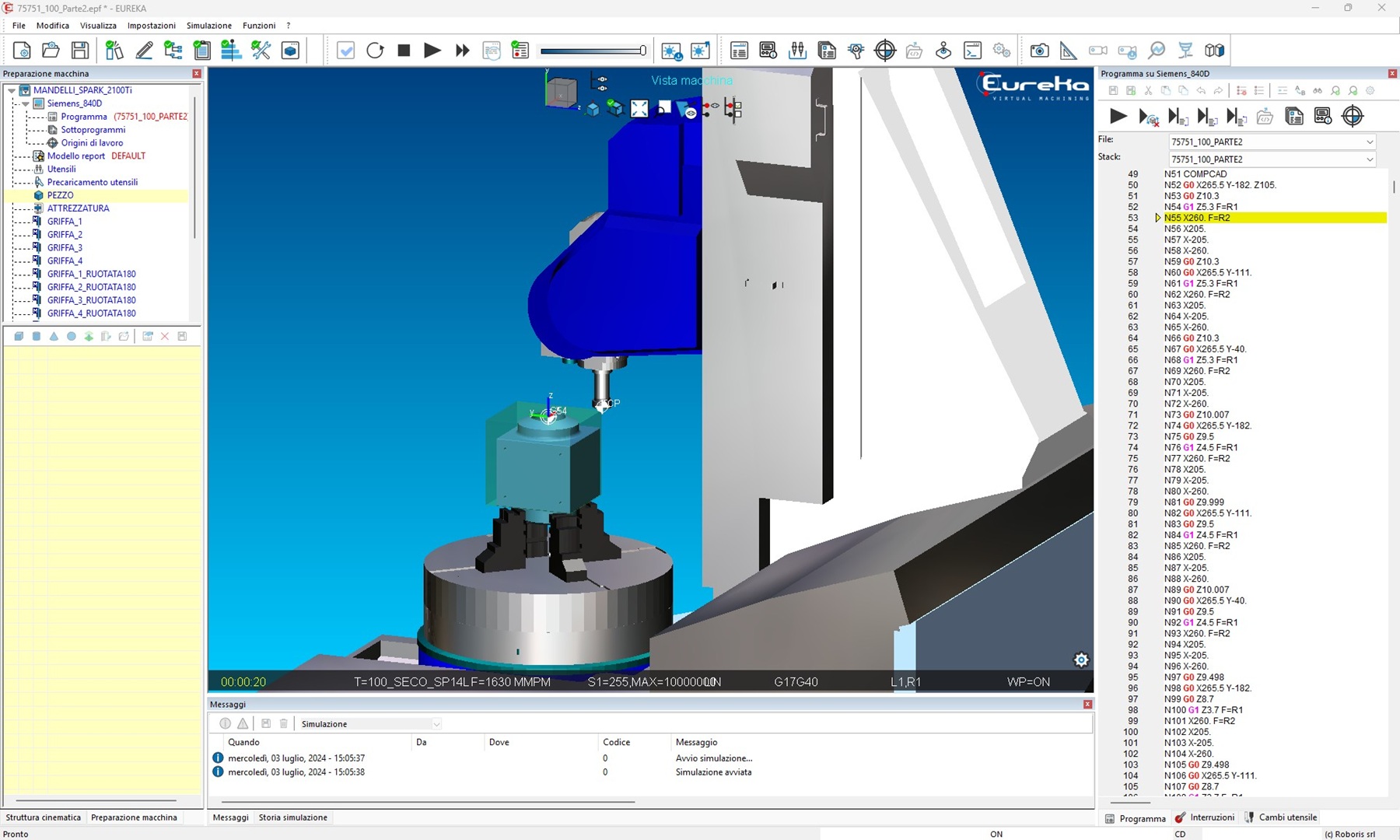

Special machining process simulation

Optimization of paths, equipment, tooling, and cutting parameters using CAD-CAM software and the associated CNC simulator.

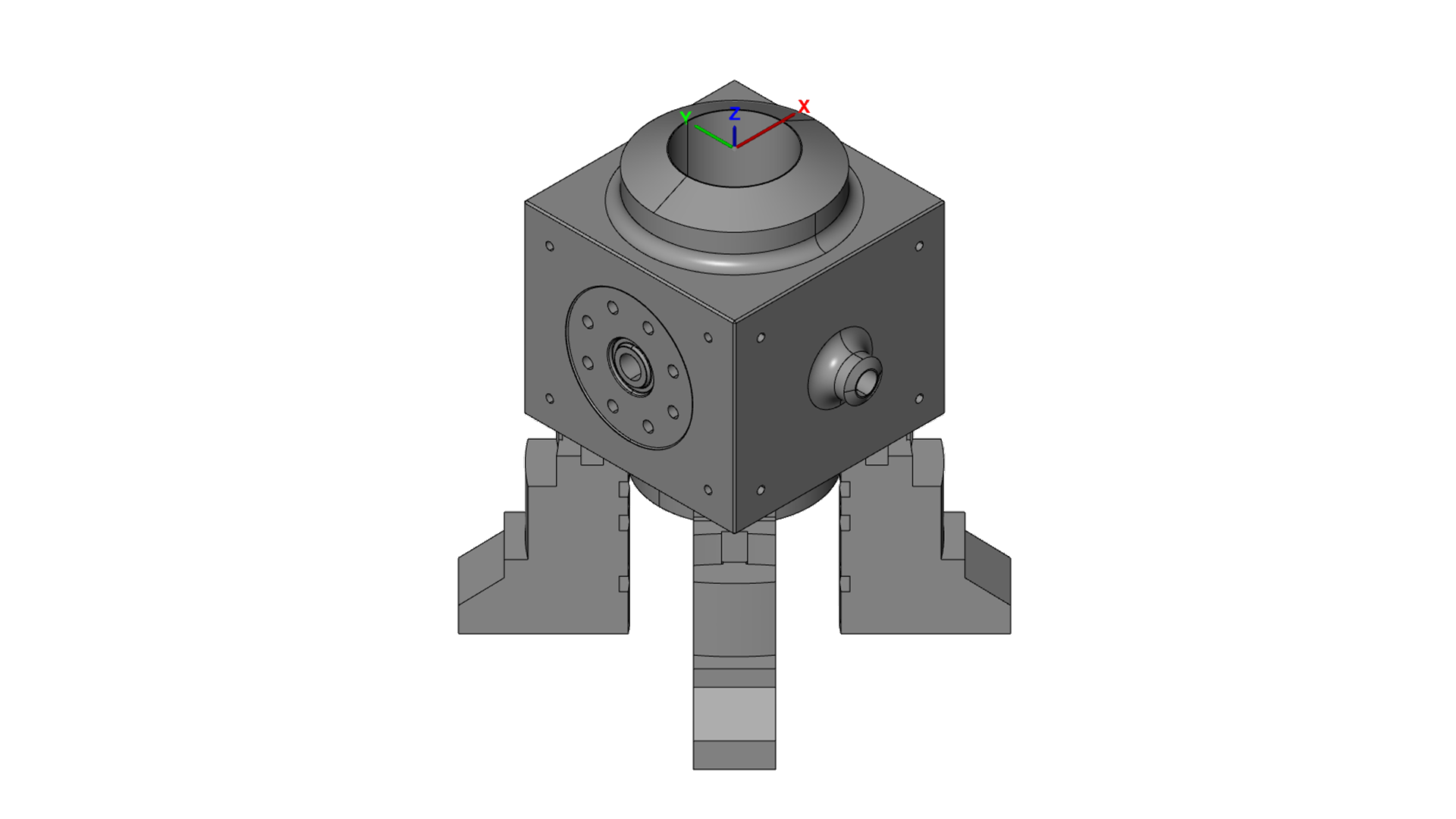

Product validation

It is carried out through the execution of operational tests under various load conditions, which involve the combined application of hydraulic pressure up to 1600 bar and bending moments