Customized Products

Customized components designed and engineered to customer specifications.

We manufacture special parts up to 5500 kg and 3500 mm in diameter.

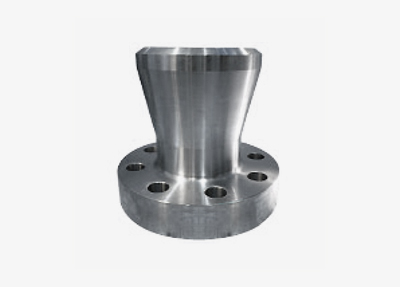

Long welding neck special

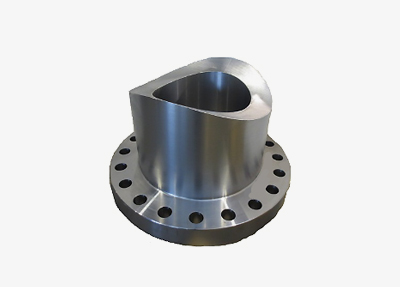

Nozzles

Spool pieces

Long welding neck compact

Penetrators

Stub ends

Anchor flanges

Y pieces

Nipo flanges

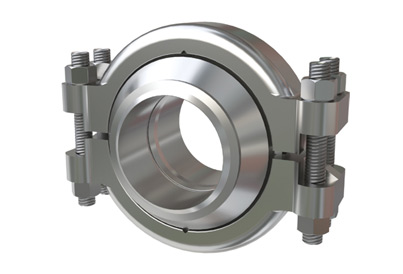

Misalignment flanges

Bulkheads

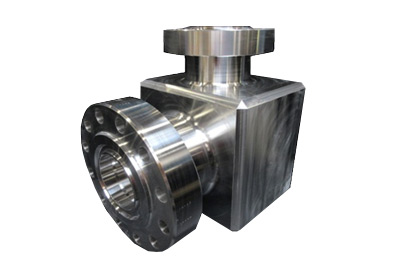

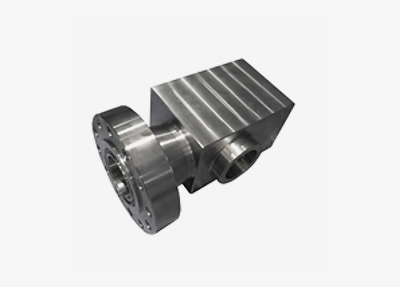

Api block

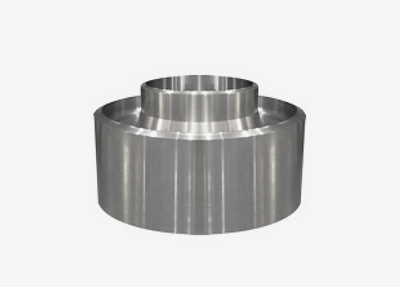

J-lay collars

Venturi

Api flanges

Swivel rings

Adaptors

Flanged bosses

Rings

Special forgings

Tube sheets

Special forgings in accordance to client drawing

Weldolet

Nozzles

Sweepolet

Shell elbow

Special flanges in accordance to client drawing or designed

Material families:

We use steel in accordance with the main international standards (e.g., ASTM) or with dedicated material data sheets according to customer specifications or design requirements.

- Carbon steel

- Low-alloy steel

- High-alloy steel

- Austenitic stainless steel

- Martensitic stainless steel

- Duplex/super duplex stainless steel

- Nickel alloys

- Copper alloys

- Aluminum alloys

- Titanium

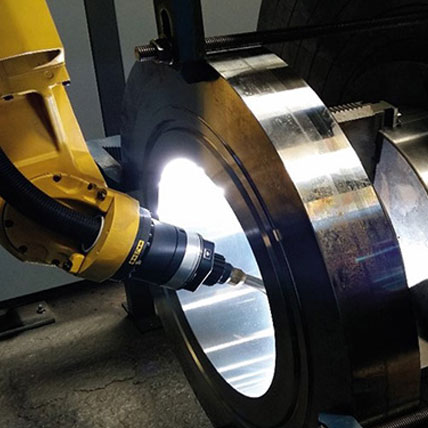

Anti-corrosion overlay welding:

Main materials used for anti-corrosion overlay welding:

- ER NiCrMo-3 (inc 625);

- ER 309L Mo + ER 316L Si (F316);

- ER 309L Mo + ER 310 (F310);

- ER NiFeCr-1 (inc 825);

- ER NiCrMo-4 (hast C276);

- ER 2209 (F51);

- ER NiCrMo-13 (alloy 59).

The engineering is the design phase, the optimization, the experimentation and the validation of the products.

Technology and know how confirm the validity of the results through the simulation that allows to predict the behavior of the systems and validated by the practical tests.